B Deep Rotor Sand Making Machine

B Series Sand Making Machine integrates three crushing methods into one. It is the core equipment in sand making industry. It incorporates three crushing styles: material on material, material on iron and falling at side.

Key Parameters

Capacity: 60-520t/h

Max. Input Size: 45mm

Material: cement, refractories, abrasives, glass production, aggregate, sand, metallurgical, iron ore, non-ferrous metal ore, corundum, bauxite, quartz sand, basalt, etc.

Advantages

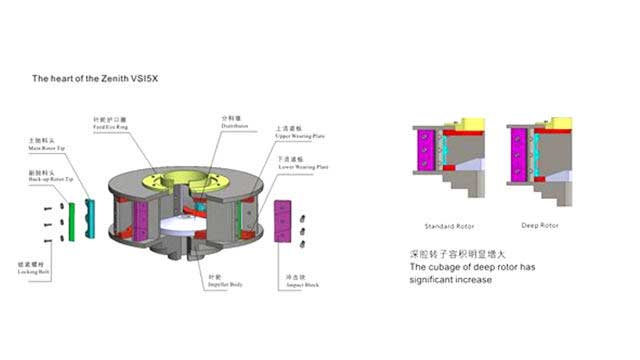

- Deep cavity-type rotor design is optimized to increase pass-through volume of material by 30%.

- Modular-design hammer makes replacement of worn parts easier and can reduce cost by more than 30%.

- The core parts are highly wear-resistant and heat-resistant.

- Diamond-shaped impact block avoids stand plate being damaged after wear-out.

- Bearings are from famous Swedish and American brands.

- Optimal shooting mouth and smoother curve-shaped design reduce the resistance to the material flow, improving pass-through capacity as well.

- Special seal structure at the end of the spindle ensures no oil leak.

- Parts of hydraulic openings are imported from Japan. It is easy and quick to move upper lid, so the internal mechanical overhaul and replacement need less labor effort.

- Using high protection motor to keep high efficiency and low noise.