Calcite Grinding

Calcite, widely distributed, which hardness is 2.7-3.0, specific gravity is 2.6-2.8. Its main component is calcium carbonate.

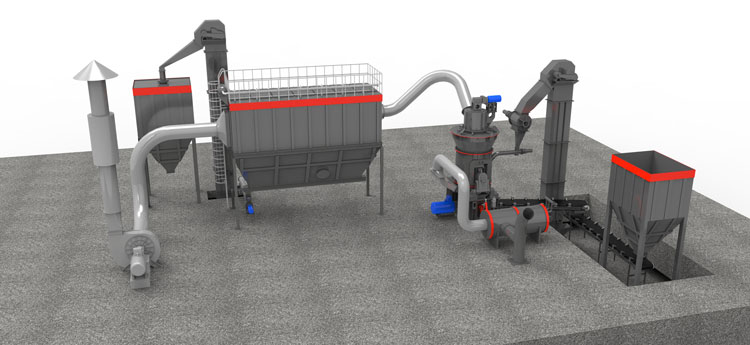

LM System

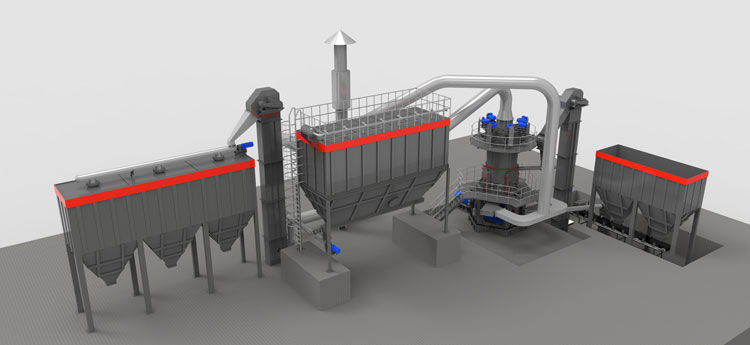

LM System LUM System

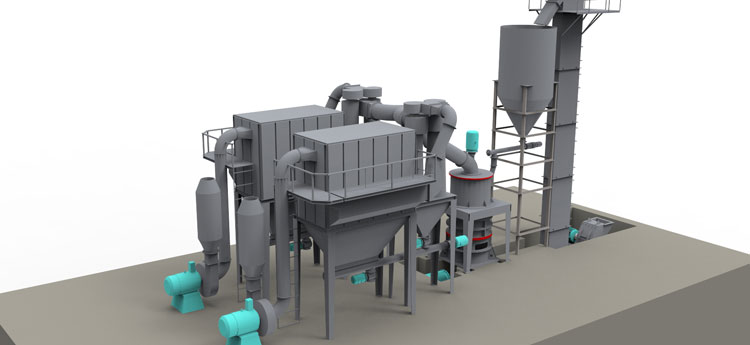

LUM System MTW System

MTW System XZM System

XZM System1. Crushing stage: The bulk material is crushed to feed fineness (15mm-50mm) of the mill.

2. Grinding stage: Small pieces satisfying the grinding conditions are grinded into powder in the grinding chamber.

3. Classification stage: The material after grinding is classified by the separator.

4. Pulverizing stage: Fine powder enters the pulverizing system. The finished powder is sent to the warehouse, and then packed.

Application: used in the production of chemical, cement and other industrial raw materials

Production fineness: <325mesh

Usually it is used in the production of chemical, cement and other industrial raw materials. It is also used as filling additive in food; added calcite in glass production.

Application: used for making high quality putty powder

Production fineness: 400-800mesh

It can be used for making high quality putty powder, plastic, paper, toothpaste, soap and so on.

Application: used in the production of rubber, plastics, cables and PVC

Production fineness: >800mesh

It is used in the production of rubber, plastics, cables and PVC (whiteness above 94 degrees).

Application: used as raw materials for paints, coatings, inks, etc.

Production fineness: >1250mesh

It can be used as raw materials for PVC, PE, paint, paint grade products, paper primer, paper surface coating and ink.

Get Solution & Price Right Now!

leave your message here, we'll send you

an Email immediately.