Tanzania 100-120TPH Granite Crushing Project

Design Scheme

Material: Granite

Max Input Size: 500mm

Output Size: 0-5mm, 5-10mm, 10-20mm

Capacity: 100-120t/h

Equipment: PE600*900 Jaw Crusher; S51” Jaw Crusher; Hopper; Vibrating Screen; Vibrating Feeder

Voltage: 380V 50Hz

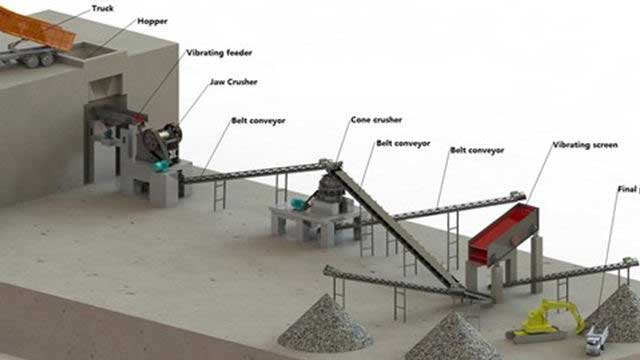

Configuration & Process of the Crushing Project

Main Equipment:

| No.. | Equipment | Model | Power(KW) |

| 1 | Hopper | LC3000X4000 | / |

| 2 | Vribrating | Feeder | GZD960*3800 15 |

| 3 | Jaw Crusher | PE600*900 | 75 |

| 4 | Jaw Crusher | S51” | 185 |

| 5 | Vribrating | Screen | 3YK860 22 |

Project Advantages

1. Well performance and stable operation

As the main machines in this plant, PE series jaw crusher and S series cone crusher have been proven to be well-performing and stable.

2. Easy operation & maintenance

It is easy to operate and maintain the crushing line.

3. Rapid installation

ZENITH experienced engineer installed crushing line within a month, allowing the customer to get investment back soon.

4. Prompt after-sale service:

We have our office set in Nairobi, Kenya, and we have experienced engineer there, who can provide prompt and good after-sales services for East Africa countries.